Have you been thinking of starting up a screen printing business or adding screen printing services to your company? Getting started is easier than you might think. We explored and compared the best screen printing machines on the market for small-business use and compiled them into an easy-to-follow ranking list.

Whether you’re a budding entrepreneur or the owner of a thriving small business who’s eyeing the next opportunity for growth, we’re sure one of these screen printing machines will help you reach your goals.

BP’s Picks for Best Screen Printing Machine for Small Businesses

- Best Overall: SHZOND 4 Color 1 Station Silk Screen Printing Machine with Removable Pallet

- Best Entry-Level Screen Printers: Simple Single 1 Color 1 Station NS101 Screen Printing Machine and INTBUYING Silk Screen Printing Press 1 Color

- Best Multi-Station Screen Printers: VEVOR 4 Color 4 Station Silk Screen Printing Machine and Techtongda 6 Color 6 Station Silk Screen Printing Press Machine

- Best for Printing on Cups, Mugs, and Bottles: VEVOR Manual Cylinder Screen Printing Machine

- Best Heat Press Machine: Seeutek 8 in 1 Power Heat Press Machine

- Best Kits for Starting a Screen Printing Business: Speedball Advanced All-In-One Screen Printing Kit and Silk Screen Printing Machine 4 Color 4 Station Kit

What to Look For in a Screen Printing Machine For Small Business Use

Trying to understand the specifications of screen printing machines isn’t always easy. To get started, consider the following important factors in choosing the best screen printing machine for your small business:

- Color and Station Capacity: How many colors can a screen printing machine print without having to remove frames? How many products can you set up for printing at one time?

- Price Point: How much do the best screen printing machines cost? What kind of value can you expect from a screen printing machine at a price point that fits your budget?

- Versatility: What type of products and materials can you print on with a particular screen printing machine?

- Features: Does it have technical features that can make a screen printing machine easier to use and more precise in its results?

- Manual Versus Automatic: Is it manual or automatic? Both variations use screen printing technology to create designs, but manual machines require hands-on work from you or your employees — something not needed when you have an automatic screen printing machine.

Color and Station Capacity

When we talk about “big” versus “small” screen printing machines, we’re not necessarily referring to the physical dimensions or weight of the machine (although the space a machine takes up can be another important consideration for small business owners, too). We’re more concerned with the capacity and capabilities of the screen printing machine. Two aspects of screen printing machines are used to measure its capabilities: color and station.

Color Capabilities

Measuring the color capacity of a screen printing machine means looking at how many separate frames of ink the machine can hold at one time. A machine can only hold one frame per arm and can only print in one color per frame. If you want to screen print only one-color designs, a machine that consists of just one arm will accomplish this task with ease and simplicity.

Suppose you wanted to print a design with two colors, or three, or even six. You can use a one-color machine to do this, but it’s going to take a lot longer. In between each color you use in your design, you would need to change out the screen and ink attached to the arm. That’s why small businesses that routinely do multicolor printing find it more efficient to invest in a machine with multiple arms.

Screen printing machines usually express the number of colors they are able to use at a time — the number of arms they have — as “1 Color,” “4 Color,” “6 Color,” and so on.

Station Capacity

To actually print on a shirt or other object, regardless of how many colors you are using, you must load that material securely onto a station. This station holds the product while you print the design on it.

The simplest screen printing machines have only one station, which means you can only work on one shirt at a time. You may be able to use multiple colors if your single-station machine has multiple arms to hold frames of different colors of ink.

However, you can’t produce the same one-color or multicolor design on multiple shirts at once. Instead, you would have to load one shirt onto the station, print the design in all desired colors, carefully remove that shirt from the station to dry and load the next shirt onto the station for printing.

Bigger screen presses have multiple stations, usually in even numbers like two, four, six, or eight. The best screen printing machines typically have at least as many arms as they do stations, and some — especially the best 1 Station screen printing machines — have more arms for holding ink colors than stations. With more stations, you can set up multiple shirts or other products to print on at a time, even if you can’t perform the actual screen printing functions all at once.

A screen printing press 4 Color 1 Station machine consists of four arms to hold ink colors and one station onto which you can load a shirt or other product. A 4 Color 4 Station machine, on the other hand, has four arms to hold ink colors and four separate stations where you can prepare a product to be printed.

In a multicolor printing machine or a multi-station machine, the arms, base, or both typically rotate 360 degrees so you can apply each color of ink to the product secured on each station.

Price Point

Although you want to invest in your company’s future, the reality is that small businesses have to stay within their budgets to survive. Going into excessive debt to try out screen printing isn’t a wise decision. That’s why we identified the best screen printing machines at a variety of price points, including list prices around $100, to make sure every small-business owner can buy the screen printer that fits their needs and budget with confidence.

Keep in mind that, when you’re looking at the cost of a screen printing machine, it’s also important to consider the value it offers. That means weighing the expense (and where it fits in your budget) against the features, efficiency of use, and other factors that put a specific press among the best screen printing machines on the market.

One final point to keep in mind when buying a screen printing machine for your small business is that your investment in the company doesn’t end at purchasing a screen printer. Unless you buy a complete screen printing kit, you’ll need to budget for the necessary materials and tools, including ink, screen frames, and drying racks.

You also need to buy the materials you plan to print on, such as T-shirts, mugs, and fabric tote bags. These costs can add up, so factor them into your decision when choosing what price point you’re considering for a screen printing machine.

Versatility

Did you know that different screen printing machines are made to print on different materials, products, and shapes? Before you buy, it’s crucial that you think hard about what you intend to use your machine to create. Most screen printing machines work on flat surfaces, but some are limited to apparel and other fabric materials, while others are also suited to printing on glass, wood, ceramic, leather, and more.

You can also buy screen printing machine models that are made for printing on cylinder- and cone-shaped products, including everything from mugs to ballpoint pens.

A more versatile machine isn’t always better, but it may be a better choice for your small business, depending on your goals. If you’re strictly interested in creating T-shirts and apparel, a screen printing machine without these added material compatibilities may work just fine. If you envision offering a whole line of printed products for retail sale or order, then you may find an entry-level screen printing machine too limiting for your needs.

Features of the Best Screen Printing Machines

Different screen printing machines offer different technical features. You don’t necessarily need to have all the latest and greatest features for your screen printing business to be successful, but some fairly common features make these machines easier to operate.

For example, an adjustable screen clamp can be moved to change the screen frame without much hassle. The maximum size of the screen clamp determines how thick your frame can be. A removable pallet allows for easy adjusting and for printing multiple images.

An adjustable spring device can help you get the perfect amount of tension, achieving great-looking results with less mess. Some machines use a system of adjustable double-spring devices for better control. Metal construction may make for a more durable, long-lasting machine.

Manual Versus Automatic Screen Printing Machines

Manual screen printing machines work by hand-squeegeeing colored ink onto the surface of the product through a mesh frame containing a design. An automatic screen printing machine uses this same process of printing ink through a mesh frame, but the machine applies the ink for you.

Being able to skip the step of squeegeeing designs by hand speeds up production considerably, but there’s a huge tradeoff that most small businesses can’t surmount: the cost. To invest in a fully automatic screen printing machine, you’re looking at an upfront cost of tens of thousands of dollars, even for the most entry-level printers. The most efficient high-end automatic machines on the market can run in the range of several hundred thousand dollars for a single machine.

Since this massive cost just isn’t in the realm of possibility for most small businesses, we focused instead on ranking the best manual screen printing machines.

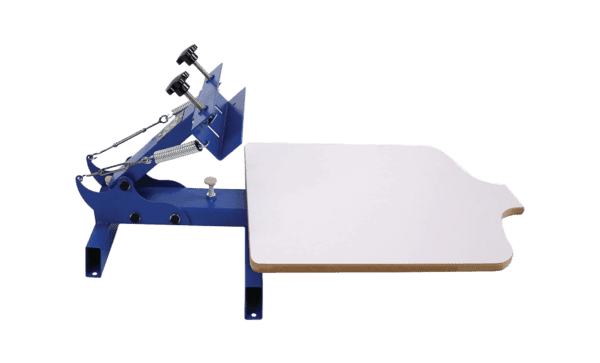

Best Overall: SHZOND 4 Color 1 Station Silk Screen Printing Machine with Removable Pallet

Just because your business is small doesn’t mean your ambitions are small, too. You want to be able to handle complex multicolor screen printing projects in a quick and cost-effective manner, but you need to stay at a price point that fits your budget. The SHZOND 4 Color 1 Station Silk Screen Printing Machine With Removable Pallet is the all-around best screen printing machine for small-business needs because it checks off all of these boxes and more.

What Makes It the Best?

Most screen printers can print with only one color of ink per station. That means a typical 1 station printer can only use one ink color at a time. SHZOND’s 4 Color 1 Station silk screen printer is exceptional because, as a 4 Color 1 Station model, it has four distinct arms that you can use to print up to four colors of ink for a single project. The arms spin to align with the single screen printing press station.

If you’re going to do multicolor projects, a 4 Color 1 Station screen printing machine really speeds up the process versus having to swap out the ink every time you need to use a different color.

Because this model by SHZOND only has one station, it’s a lot more suitable for really small businesses like new startups, home-based businesses, or companies with limited space and budgets. Multi-station screen printing machines like the VEVOR 4 Color 4 Station Silk Screen Printing Machine and the Techtongda 6 Color 6 Station Silk Screen Printing Press Machine take up a lot more space than this SHZOND model’s single station does.

These larger machines also cost a lot more. At a price point of just $165, the SHZOND multicolor printing press is a great value as well as being the best screen printing machine in its own right.

The SHZOND 4 Color 1 Station machine printing press is super versatile. It can print on flat surfaces of just about any materials — not just clothing but also any type of woven fabric as well as plastic, paper, wood, and metal. If T-shirts are your primary focus, though, you’ll love the specially designed T-shirt pallet that offers maximum accuracy for perfectly executed designs.

The removable pallet is a remarkable feature because it allows you to conveniently move and adjust the position of the pallet in every direction. This feature allows you to print multiple images at a time. The adjustable screen clamp and purposefully designed spring devices make it easy to hold screen frames up to 1.8 inches thick and minimize the mess of ink spills and splashes.

What’s Missing?

The number one complaint buyers had about the SHZOND 4 Color 1 Station machine was assembly. Users universally agreed that neither the written instructions nor the instructional video did much to help them assemble the screen press. Some buyers complained about missing hardware — nuts and bolts that, while easy enough to replace, required a frustrating, urgent trip to the hardware store.

To many purchasers, it appears at first glance that the holes don’t line up correctly to assemble the piece properly. Before you get out your drill or start writing an angry message to the seller, be aware that you have to use the small hex key — included in the package — to adjust the arms so that they align correctly with the holes.

Skipping this step won’t only cause a lot of headaches and extra work trying to modify the components of the machine. It could also mean that, once you get the machine together, you’re not able to align the arms correctly for printing precision.

Once the screen printing machine is correctly assembled, the biggest drawback is that it doesn’t offer the expedited production of multi-station machine screen printing press models like the VEVOR 4 Color 4 Station machine or the Techtongda 6 Color 6 Station machine. If you want the power of two, four, or six stations, then you’re going to need to spend a lot more.

Additionally, the low price point of the SHZOND 4 Color 1 Station machine is easily within budget, but keep in mind that it doesn’t include any of the materials or other tools you need to begin shirt printing or doing other types of multicolor printing projects. The screen printing machine press itself is just the tip of the iceberg in this business. You need a lot more to get started, including ink, screen frames, and T-shirts or other materials to print on.

Best Entry-Level Screen Printers: Simple Single 1 Color 1 Station NS101 Screen Printing Machine and INTBUYING Silk Screen Printing Press 1 Color

If you’re new to the business of screen printing, an entry-level machine may be your best option. Models like the Simple Single 1 Color 1 Station NS101 Screen Printing Machine by Commercial Bargains and the INTBUYING Silk Screen Printing Press 1 Color are easy to use even for beginners and allow you to jump into the screen printing business without taking up too much of your budget or your space.

Simple Single 1 Color 1 Station NS101 Screen Printing Machine

What Makes It the Best?

At under $120, the Simple Single 1 Color 1 Station NS101 Screen Printing Machine by Commercial Bargains is hard to beat in terms of value. This screen printer boasts a stainless steel metal construction that makes it easy to clean as well as rust resistant. Although made of metal, the machine is lightweight, weighing just 25 pounds.

The simplicity of this screen printing press makes it ideal for a small-business owner still learning the trade. With adjustable double-spring devices that allow you to achieve just the right amount of tension and a dedicated T-shirt pallet, it’s easy to create precisely printed designs without the hassle. The screen clamp allows you to easily lock your screen in place to avoid imperfections that waste your time and materials.

Everything about the use and operation of this printing machine is made to be simple, streamlined, and easy to use even for beginners.

What’s Missing?

As with the SHZOND 4 Color 1 Station machine, assembly was the one aspect of the Simple Single NS101 machine that buyers most complained about. Missing or confusing instructions made the machine difficult to put together for some users, although assembly of a 1 Color 1 Station silk screen printing machine is a lot less complicated than putting together a machine with multiple arms or stations.

The smaller size and lightweight construction may make you think you can just set up the machine on top of a desk or table, but you really shouldn’t. Mount the screen printer to a counter or table to keep it safely secured so it won’t tip, tilt, or fall — putting you and your employees or customers at risk of injury and preventing your designs from coming out perfectly.

Because this screen printer is smaller and simpler, it doesn’t have many of the same capabilities as higher-end models. For example, the screen clamp only holds frames up to 0.78 inches thick — not even half the thickness that the SHZOND 4 Color 1 Station machine can hold.

If you want to do more than print single-color, single-screen T-shirts, you’ll be disappointed by the Simple Single NS101’s lack of versatility. This one-color machine isn’t built for multicolor printing or for jobs that require multiple screens. It’s intended for T-shirt printing and printing on non-woven bags, pillowcases, and other non-woven fabric items.

The Simple Single NS101 machine doesn’t offer the same range of possible uses as you’ll find with the SHZOND 4 Color 1 Station machine or the VEVOR 4 Color 4 Station Silk Screen Printing Machine.

INTBUYING Silk Screen Printing Press

What Makes It the Best?

At a price point of $139, the INTBUYING Silk Screen Printing Press doesn’t cost much more than the Simple Single NS101 model, but it gives you a lot more utility. Express your creativity on a wider range of media and materials — including woven fabric, wood, plastic, and paper — to expand and diversify your line of merchandise.

We love that the lever and handgrip, along with a series of specially designed arms and clamps, allow you to easily adjust the height and angle of the pallet for better accuracy. If you want an affordable option for printing on flat materials of all kinds and don’t mind being limited to one-color designs, the INTBUYING 1 Color 1 Station Silk Screen Printing Press may be just what your small business needs to flourish.

What’s Missing?

Most of the drawbacks to the INTBUYING Silk Screen Printing Press mirror those of the slightly cheaper Simple Single NS101 model. You’re limited to using screen frames 0.78 inches thick. You need to mount it to a tabletop for safety reasons (and a bracket is not included). Assembly is, again, the biggest complaint buyers have.

Some users noted a different problem: rough edges that can catch and damage delicate fabrics. This problem can be easily and inexpensively fixed by covering any rough spots with edge banding tape, but if you don’t address it, it could end up costing you time and resources as you have to redo your work.

As a single-station screen printing press, the INTBUYING model doesn’t process the volume of work that a multi-station press does. For your first foray into screen printing, though, it has a lot to offer considering how small an investment you’re making.

Best Multi-Station Screen Printers: VEVOR 4 Color 4 Station Silk Screen Printing Machine and Techtongda 6 Color 6 Station Silk Screen Printing Press Machine

The more stations your screen printer has, the more projects — and more complex projects — you can handle at a time.

Suppose you plan on taking bulk orders in your screen printing business. Maybe you make shirts printed with a company logo for a larger business, or perhaps you want to mass produce a design to sell in your store. To do this efficiently, you need more than a one-station machine like the SHZOND 4 Color 1 Station printer, the Simple Single 1 Color 1 Station NS101 Screen Printing Machine, or the INTBUYING Silk Screen Printing Press 1 Color machine.

Multi-station machines like the VEVOR 4 Color 4 Station Silk Screen Printing Machine and the Techtongda 6 Color 6 Station Silk Screen Printing Press Machine allow you to set up multiple jobs or inks at a time. This allows you to create more complex designs with multicolor printing and get through your printing workload faster.

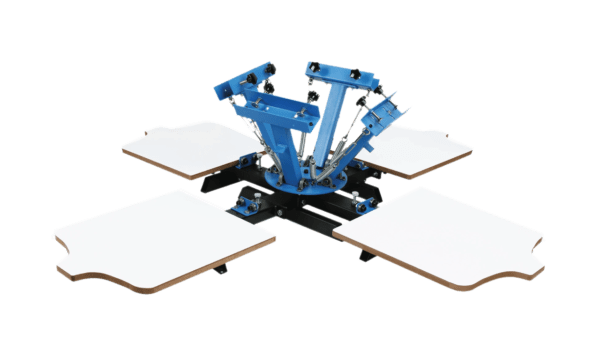

VEVOR 4 Color 4 Station Silk Screen Printing Machine

What Makes It the Best?

The VEVOR 4 Color 4 Station Silk Screen Printing Machine boasts an easy-to-clean and rust-resistant metal construction. The 360-degree rotating design allows you to set up four colors with four different screen frames (designs) and rotate them through your four printing stations as needed. Specially designed and manufactured bearings are made to withstand the mechanical stress that comes with long-term, heavy-duty use.

This process is way faster than having to swap out a single-color head for every ink color change you need to make, especially if you’re making multiples of the same design. Line up and quickly commence screen printing on four shirts at a time, rather than having to repeat the cycle of loading, printing, and removing a shirt four times as you would on a machine with a single station.

The VEVOR 4 Color 4 Station Silk Screen Printing Machine is capable of printing on a huge selection of flat materials. Besides woven fabric, paper, plastic, and wood, it’s also suitable for pressing designs onto ceramic, leather, and even glass.

This professional-grade screen printing machine includes a removable and adjustable pallet. Spring devices on each arm are made especially to ensure there’s the right amount of tension and intensity on each screen frame, regardless of the size and weight of the frame. The screen clamp can accommodate screens up to 2 inches thick.

Listed at just $289.99 on the manufacturer’s website ($325.99 on Amazon), this screen printing press offers a lot of bang for your buck, and its space-saving design means that, for a 4 Station model, it won’t take up any more space than necessary.

What’s Missing?

Assembly is, once again, the chief complaint. For small-business owners, spending hours putting together a machine, even one that will ultimately ramp up your production speed, is a frustrating tradeoff.

The good news is that, once assembled, this machine really does seem to meet users’ expectations, especially at this price point. If you’re in the market for a manual screen printing machine of this size and capability, you can’t do much better than VEVOR’s 4 Color 4 Station Silk Screen Printing Machine.

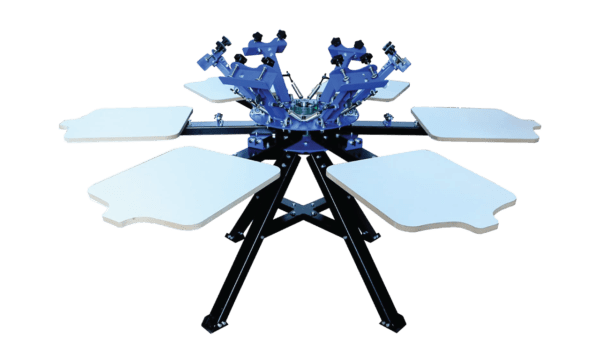

Techtongda 6 Color 6 Station Silk Screen Printing Press Machine

What Makes It the Best?

If you’re willing to spend a bit more money to get more out of your screen printing machine, take a look at the Techtongda 6 Color 6 Station Silk Screen Printing Press Machine. This heavy-duty option can produce as many as 50 six-color printed T-shirts in an hour, boosting your efficiency, productivity, and profits.

Like VEVOR’s 4 Station machine, you can use the Techtongda 6 Color 6 Station to screen print on everything from woven fabric to wood, metal, paper, glass, leather, and ceramic tile. The pallet and the screen frame both rotate 360 degrees (independent of each other) for fast and easy-to-use operation when you’re working on multiple projects or bulk orders.

With six separate heads for ink, this machine allows for more color combinations than any other screen printer on our list. The screen clamp holds screen frames up to 2 inches thick.

What’s Missing?

You’ll spend more on this overachieving 6 Color 6 Station Screen Printing Machine. This Techtongda model is listed on Amazon for $739, with a shipping charge of $250.

That’s still pretty reasonable compared to the industrial-level manual machines for larger businesses, which can easily cost several thousand dollars, and the high-end automatic machines for which the big companies pay tens of thousands, if not hundreds of thousands of dollars. However, for a small-business owner — especially a new entrepreneur — it’s a noticeably steeper cost than most of the other screen printing machines on our list.

The more complicated the machine, the more help you will need to run it at full capacity — and 6 Color 6 Station screen printing can get fairly complicated. If you want to complete a job of printing 50 six-color T-shirts in an hour, you’ll need two people to run the machine. While the potential can certainly raise your revenues, the need for a second operator can also increase your overhead costs.

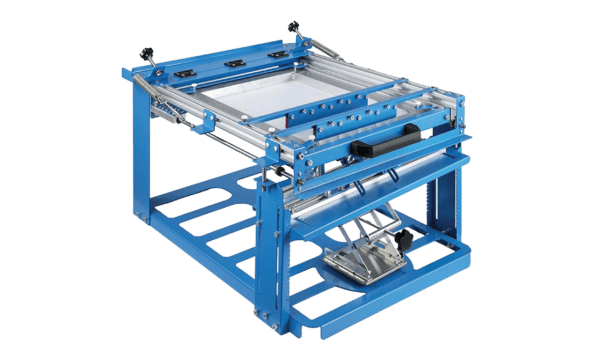

Best for Printing on Cups, Mugs, and Bottles: VEVOR Manual Cylinder Screen Printing Machine

T-shirt printing is probably the most common use of screen printing machines. If you want to print on more than just clothing and other flat surfaces, you’ll need a different kind of screen printing machine: a cylindrical screen printing press. For small-business owners, the best screen printing machine for cylindrical items is the VEVOR Manual Cylinder Screen Printing Machine.

What Makes It the Best?

Let’s face it — if you’re only printing on flat surfaces, you’re missing out. Cups, mugs, water bottles, wine glasses, and similar products are huge sellers, especially when it comes to gifts and souvenirs. The VEVOR Manual Cylinder Screen Printing Machine can print on all of these items, plus pens, candles, wine bottles, bracelets, cosmetic bottles, baseballs, fishing rods, and more. Just about any item with a cylinder or cone shape is fair game.

To print on cylinders of different sizes, a screen printing machine must both hold and turn the item on which you’re printing while you operate the squeegee. VEVOR’s Manual Cylinder Screen Printing Machine uses an adjustable lift and an adjustable base for holding the cylindrical items on which you’re printing to accomplish this in an easy-to-use way.

A nonslip handle makes it easy for the operator to control the machine. The steel plate metal construction makes for a study machine that screen prints with precision.

The VEVOR Manual Cylinder Screen Printing Machine comes in two sizes. The small 200-millimeter-by-100-millimeter size is priced at just over $200, while the larger 200-millimeter-by-240-millimeter size is listed at just under $280. At these price points, either model of this cylindrical screen printing press will expand your product line without breaking the bank.

What’s Missing?

You can’t use a machine like this for shirt printing and printing on other flat surfaces. If you opt for a cylindrical screen printing press like VEVOR’s in place of a flat screen printing press, you’re going to be limited. For many screen printing businesses, a cylindrical printing press is an added cost — one that might not be affordable during the startup phase or other times when your budget is tight.

Some buyers report receiving damaged parts and needing to contact the manufacturer for replacements due to packaging failures, so hold off on booking any major projects until the machine is in your possession and fully operational. Although the item comes with a screen, the custom size of the screen that fits this machine may make it difficult to find replacements should you wish to buy extra screens or replace old or damaged ones.

Best Heat Press Machine: Seeutek 8 in 1 Power Heat Press Machine

Strictly speaking, heat press is a different technology from screen printing. If you’re more interested in the functionality than in how your machine manages to put a permanent design on an item, consider launching your business with the Seeutek 8 in 1 Power Heat Press Machine.

What Makes It the Best?

As the name suggests, a heat press uses heat to press a design onto a shirt, bag, cup, hat, or other item. Heat pressed designs are an additional layer of ink that rests on top of the item, rather than merging with it the way screen printed ink does. Through heat pressing, you can create merchandise made with complex designs and virtually unlimited color combinations and achieve crisp and appealing results.

You get more for your money with a heat-press machine than you do from a screen printing machine press. Listed at a price point of just $265, the Seeutek 8 in 1 Power Heat Press Machine is a full kit that excels in versatility. Print on everything from T-shirts and textiles to ceramic plates and tiles, mouse pads, jigsaw puzzles, leather, glass, and metal.

The Seeutek 8 in 1 Power Heat Press Machine is another option if you want to print on merchandise that isn’t flat. This press comes with attachments and accessories needed to press heat-transfer designs onto mugs of various sizes as well as hats.

The Seeutek 8 in 1 Power Heat Press Machine is easy to clean, no squeegee or mesh frames required. With a swing-away design that allows for full 360-degree rotation, you can adjust the heat source’s position as needed and avoid the risk of burning yourself (or your employees burning themselves).

Preset temperature options give you complete control over how hot the heat press gets. A built-in timer takes the guesswork out of the process, so you always end up with a perfectly pressed product.

Success in producing flawless heat-transferred designs on different materials requires flexibility, and this machine is nothing if not adaptable. An adjustment knob allows you to accommodate materials of different thicknesses with ease. The lower platform is detachable, and the silicone and cotton pads are removable.

The metal construction of the Teflon-coated aluminum heating plate is ideally suited to the job of transferring printed designs without the designs sticking to the plate or the heat source, burning your materials.

With the heat-transfer machine itself fully assembled upon arrival, setting up the Seeutek 8 in 1 Power Heat Press Machine is a lot easier than setting up many of the screen printing machines on our list. Users reported setting up the press and successfully printing their first project on it in as little as 45 minutes — a stark contrast to the hours that purchasers of manual screen printing machines reported spending on installation.

What’s Missing?

There’s a reason why screen printing is widely considered a better method of permanent design marking than heat transfer. Screen printed designs are typically more durable. They last longer and sustain less wear and tear — for example, cracking and fading of the ink — than designs created through heat transfer.

If the items you’re printing are going to be washed heavily, such as T-shirts or drinkware, the heat transfer printing process won’t achieve as good long-term results as screen printing. When creating items that won’t suffer as much use and handling, on the other hand, this may not be an issue.

The feel of a heat pressed design is different from a screen printed design. Heat transfer designs can sometimes feel bulky or stiff compared to the soft feel of screen printed designs. Again, how much this matters depends on what you’re printing. The feel of home decor items doesn’t matter as much as the feel of printed T-shirts and other apparel.

Although heat presses are, generally, easier to operate than manual screen printing machines — without the need for squeegees, scrubbers, films, and screens — some users had trouble learning to use the Seeutek. Others complained of malfunctions and difficulties contacting customer service, although the majority of reviews of this heat-transfer press are favorable.

If you’re looking for a heat press that does a lot and won’t cost your small business a lot of money, the Seeutek 8 in 1 Power Heat Press Machine may be worth a look. Small-business owners who need their machine to last may want to consider purchasing an extended warranty, since the included manufacturer warranty only covers one year.

Best Screen Printing Kits: Speedball Advanced All-in-One Screen Printing Kit and Silk Screen Printing Machine 4 Color 4 Station Kit

The screen printing machine itself is probably the single most important piece of equipment you need to start a screen printing business. However, other tools, materials, and equipment are necessary for success in this line of work. Investing in a screen printing kit can streamline the process of figuring out and acquiring what you need, since these bundles come with everything your small business needs to get started.

Generally, two types of small-business owners are interested in a screen printing kit. On one end of the spectrum are the dabblers who don’t want to put a lot of money in this new business venture (or offshoot) until they’re certain it’s going to pay off. On the other end of the scale are the determined business owners who have no reservations about going whole hog into the screen printing business.

For dabblers, we recommend the Speedball Advanced All-in-One Screen Printing Kit. For serious screen printing hopefuls, we suggest the Silk Screen Printing Machine 4 Color 4 Station Kit.

Speedball Advanced All-in-One Screen Printing Kit

What Makes It the Best?

Suppose you’re just toying with the idea of launching your own screen printing business, but you want to take action. Maybe you already have an established retail store or other business, and you’re considering growing it by offering your own screen printed or personalized products. Either way, the great thing about the Speedball Advanced All-in-One Screen Printing Kit is that it’s so affordable and requires so little technical knowledge that anyone can use it.

At a price point of just $99, the Speedball kit fits any company’s budget. The financial consequences, if you decide a screen printing business isn’t right for you, are very, very low. It’s not like you wasted several hundred dollars on a machine that’s going to sit on a shelf collecting dust.

The Speedball Advanced All-in-One Screen Printing Kit includes everything you need to manually screen print any design you can imagine. By using a photo emulsion process to create your own unique stencils to print from, you can easily create designs with clear, crisp details.

Since there’s no computerized screen printing press — only the wooden frame and base and the squeegee used to manually spread emulsion and ink — you don’t have to be tech savvy to learn how to operate a machine. That makes this choice particularly ideal if you’re more proficient with hands-on skills than computer use.

The modest-sized frame is a space-saver, especially compared with multi-station workhorses of machine screen printing models that take up a ton of real estate. This small size is one more reason why Speedball’s kit is ideal for a home-based business or a small shop where space is at a premium.

The kit includes the lamp and photoflood bulb you need to perfect your stencils and four jars of ink, starting you off with the capability to screen print in black, white, blue, and red. We love that the inks included in the Speedball Screen Printing Kit are water-based, making the tools and equipment easy to clean. Just wash the excess ink right down the drain.

The kit also includes step-by-step instructions, including a video tutorial, that makes it easy to use even for beginners.

What’s Missing?

The Speedball Advanced All-in-One Screen Printing Kit contains all the necessities for the screen printing process, but if you’re set on having a screen printing machine, you’ll be disappointed. Because you have to do the work by hand, you can expect the job to be messier and more time consuming than having a screen printing press handle the task of spreading the ink for you (with your help).

Although this under-$100 price tag is appealing, business owners may wish they’d spent a little more to get an actual screen printing machine. Considering that budget-friendly options like the Simple Single Screen Printing Machine and the INTBUYING Screen Printing Machine are listed at just $15 to $40 more, it’s not that high of an extra expense (although small-business owners should keep in mind that they still have to buy the ink and any other materials and tools).

Although you can use this kit to create prints in multiple colors, it’s going to be a multistep process. Like any of the 1 Color 1 Station screen printing machine models, you would need to use a separate screen for each color of ink, which means spending more time working on the design and the finished product — not to mention allowing more room for error.

This kit may make sense if you want to experiment with adding a few customized bags to your retail store’s product inventory or create and sell your own merchandise celebrating your pizza joint’s status as a local favorite. If you envision doing screen printing on a larger scale, you’ll be saving a lot of time and frustration by opting for a real screen printing machine press.

Silk Screen Printing Machine 4 Color 4 Station Kit

What Makes It the Best?

The Silk Screen Printing Kit also uses the photosensitive emulsion process to create screen designs, so it offers the same benefits of control over creativity and versatile, detailed design elements. Unlike the Speedball Kit, though, the Silk Screen Printing Kit includes a fairly heavy-duty machine capable of 4 Color 4 Station screen printing.

This kit also comes with a lot of other bells and whistles, including a 1800W Flash Dryer. An included water tank, screen frame clapboard, and automatic pressurizing water spray gun for easier and more convenient plate-washing.

The sheer number of items you get in this bundle is enough to impress, but so is the amount of these materials you get. Users estimate that you can print at least twice as many — if not up to five times as many — designs with the included materials as you could using the Speedball Screen Printing Kit.

With four stations available to run at a time, you can also get a much larger volume of work done in a much shorter span of time than you would using a manual frame like Speedball’s or a basic 1 Station silk screen printing printer.

You can’t realistically expect to take on bulk orders with the Speedball Kit, but you can with the 4 Station Silk Screen Printing Kit. Since this bundle really includes everything you need to get started, you can launch your new business right away without having to make half a dozen frantic trips to the nearest craft store as you get to each new stage of the process.

What’s Missing?

Compared to 1 Station silk screen printer, this 4 Color 4 Station screen printing kit, with all the trimmings, has a high price tag. Even if you’re eager to get all the materials and components you need to get your business running, the $1,749 cost — plus shipping charges of well over $300 — might leave you with some serious sticker shock.

Then there’s the space limitations. This 4 Station machine is basically a full screen printing workshop, and it takes up a lot of space — up to 10 square feet. If you’re worried that such a huge machine will leave your workspace feeling a bit too cramped, consider starting out with a 1 Station screen printing machine instead. You can always upgrade when you have more orders to handle and more commercial space to dedicate to the equipment.

Since this kit is made to equip a novice screen printer with everything they need to get a business up and running, you would expect it to be easy to use. Although the company advertises that video instructions are included in the purchase, several buyers complained of the machine being difficult to assemble and to figure out.

If you’re comfortable with this price point and willing to devote your space to holding this large machine — not to mention putting in the time and effort to assemble and learn to use it — you won’t find a better option than the Silk Screen Printing Machine 4 Color 4 Station Kit. It’s got everything you need to quickly break into the business and handle bulk orders from the get-go.

Conclusion

Choosing the best screen printing machines for your needs is your first step toward launching a design printing business of your own or growing your existing business in a lucrative new direction. You can do so much with a screen printing machine, making everything from clothes and bags to home decor, promotional items, everyday treasures, and more.

Whether you plan on making money by taking bulk orders for company uniforms and gear or creating and selling customized gifts and souvenirs, having one of the best screen printing machines is critical.

Every screen printing machine on our list offers excellent performance and functionality. The only question is, which screen printing machine is best for your small business?